Zida zamakono zodulira zida zakhala ndi zaka zopitilira 100 zachitukuko kuyambira chitsulo cha carbon mpaka chitsulo chothamanga kwambiri,simenti carbide, chida cha ceramicndizida zida zamphamvu kwambiri.Mu theka lachiwiri la zaka za zana la 18, zida zoyambira zidali makamaka zida za carbon.Chifukwa panthawiyo inkagwiritsidwa ntchito ngati chinthu chovuta kwambiri chomwe chimatha kupanga zida zodulira.Komabe, chifukwa cha kutentha kwake kochepa kwambiri kosagwira kutentha (pansi pa 200 ° C), zida za carbon tool zimakhala ndi zovuta kuti zikhale nthawi yomweyo komanso zowonongeka chifukwa cha kudula kutentha pamene kudula pa liwiro lalikulu, ndipo kudula kumakhala kochepa.Choncho, tikuyembekezera zipangizo zothandizira zomwe zingathe kudulidwa mofulumira kwambiri.Zomwe zimawonekera kuti ziwonetse kuyembekezera izi ndizitsulo zothamanga kwambiri.

Chitsulo chothamanga kwambiri, chomwe chimatchedwanso zitsulo zam'tsogolo, chinapangidwa ndi asayansi a ku America mu 1898. Sikuti ali ndi carbon yochepa kuposa carbon tool steel, koma tungsten imawonjezeredwa.Chifukwa cha ntchito ya tungsten carbide yolimba, kuuma kwake sikuchepetsedwa pansi pa kutentha kwakukulu, ndipo chifukwa kumatha kudulidwa mofulumira kwambiri kuposa kuthamanga kwachitsulo cha carbon tool, kumatchedwa chitsulo chothamanga kwambiri.Kuyambira 1900 ~ 1920, chitsulo chothamanga kwambiri chokhala ndi vanadium ndi cobalt chinawonekera, ndipo kukana kwake kutentha kunawonjezeka kufika 500 ~ 600 ° C.Kuthamanga kwachitsulo chodula kumafika 30 ~ 40m / min, komwe kumawonjezeka pafupifupi 6 nthawi.Kuyambira pamenepo, ndi kusakanikirana kwa zinthu zake, tungsten ndi molybdenum zitsulo zothamanga kwambiri zapangidwa.Ikugwiritsidwabe ntchito kwambiri mpaka pano.Kutuluka kwachitsulo chothamanga kwambiri kwachititsa kuti a

chisinthiko mu kudula processing, kwambiri kuwongolera zokolola za kudula zitsulo, ndipo amafuna kusintha wathunthu dongosolo la chida makina kuti agwirizane ndi kudula ntchito zofunika za chida ichi chida chatsopano.Kuwonekera ndi kupititsa patsogolo kwa zida zatsopano zamakina, kumapangitsanso kuti pakhale zida zopangira zida zabwino, ndipo zida zalimbikitsidwa ndikupangidwa.Pansi pamikhalidwe yatsopano yopanga ukadaulo, zida zachitsulo zothamanga kwambiri zimakhalanso ndi vuto loletsa kukhazikika kwa chidacho chifukwa chodula kutentha podula kwambiri.Pamene kudula liwiro kufika 700 ° C, ndi mkulu-liwiro zitsulo

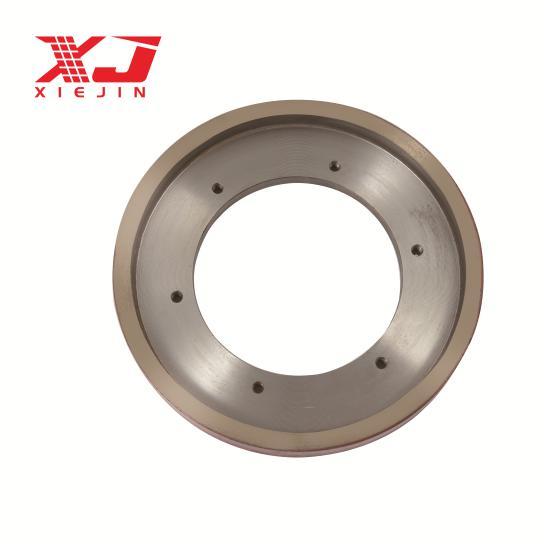

nsonga ndi yosalala kwathunthu, ndipo pa liwiro lodula pamwamba pa mtengo uwu, ndizosatheka kudula.Zotsatira zake, zida za zida za carbide zomwe zimasunga kuuma kokwanira pansi pamikhalidwe yodula kwambiri kuposa zomwe tafotokozazi zatulukira ndipo zimatha kudulidwa pamatenthedwe apamwamba kwambiri.

Zida zofewa zimatha kudulidwa ndi zida zolimba, ndipo kuti mudule zida zolimba, ndikofunikira kugwiritsa ntchito zida zolimba kuposa izo.Chinthu chovuta kwambiri padziko lapansi pano ndi diamondi.Ngakhale kuti diamondi zachilengedwe zapezeka kale m'chilengedwe, ndipo akhala ndi mbiri yakale yozigwiritsa ntchito ngati zida zodulira, diamondi zopangira zidapangidwanso bwino kumayambiriro kwa zaka za m'ma 50s za m'ma 1900, koma kugwiritsidwa ntchito kwenikweni kwa diamondi kupanga ambiri.mafakitale kudula chida zipangizoikadali nkhani yazaka makumi angapo zapitazi.

Kumbali imodzi, ndi chitukuko cha luso lamakono lamlengalenga ndi luso lazamlengalenga, kugwiritsa ntchito zipangizo zamakono zaumisiri zikuchulukirachulukira, ngakhale kuti zitsulo zothamanga kwambiri, carbide cemented, ndizida zatsopano za ceramicmu kudula kwa miyambo processing workpieces, kudula liwiro ndi kudula zokolola kuwirikiza kawiri kapena kangapo nthawi zambiri kuchuluka, koma pamene ntchito pokonza zipangizo pamwamba, kulimba kwa chida ndi kudula dzuwa akadali otsika kwambiri, ndi kudula khalidwe n'kovuta. kutsimikizira, nthawi zina ngakhale osatha kukonza, kufunika kogwiritsa ntchito zida zakuthwa komanso zosamva kuvala.

Komano, ndi chitukuko chofulumira chamakonokupanga makinandi makampani processing, ntchito lonse la zida makina basi, kompyuta manambala kulamulira (CNC) Machining malo, ndi unmanned Machining zokambirana, kuti mupititse patsogolo kukonza kulondola processing, kuchepetsa chida kusintha nthawi, ndi kusintha processing Mwachangu, zofunika kwambiri mwamsanga ndi zopangidwa kuti zikhale ndi zida zolimba komanso zokhazikika.Pankhaniyi, zida za diamondi zakula mofulumira, ndipo panthawi imodzimodziyo, chitukuko chazida za diamondi zidayakwezedwanso kwambiri.

Zida za diamondindi mndandanda wa katundu kwambiri, ndi mkulu processing kulondola, kudya kudya liwiro ndi moyo wautali utumiki.Mwachitsanzo, kugwiritsa ntchito zida za Compax (polycrystalline diamond composite sheet) zitha kuwonetsetsa kuti ma silicon aluminiyamu alloy pistoni masauzande makumi masauzande a pisitoni ndipo nsonga zawo za zida sizisintha;Makina odulira aluminiyamu a ndege okhala ndi makina odulira mphero a Compax akulu amatha kufikira liwiro la 3660m / min;Izi sizingafanane ndi zida za carbide.

Osati kokha, kugwiritsa ntchitozida za diamondi zidaKomanso kukulitsa gawo processing ndi kusintha chikhalidwe processing luso.M'mbuyomu, galasi processing akanatha ntchito akupera ndi kupukuta ndondomeko, koma tsopano osati zachilengedwe limodzi galasi diamondi zida, komanso nthawi zina angagwiritsidwe ntchito PDC wapamwamba-zovuta gulu zida kwa wapamwamba-mwatsatanetsatane pafupi kudula, kukwaniritsa kutembenukira. m’malo mogaya.Ndi kugwiritsa ntchitozida zolimba kwambiri, mfundo zina zatsopano zatulukira m'munda wa Machining, monga kugwiritsa ntchito zida za PDC, kuthamanga kwapang'onopang'ono sikulinso chida koma chida cha makina, ndipo pamene liwiro lotembenuka likuposa liwiro linalake, workpiece ndi zida osati kutentha.Zomwe zimakhudzidwa ndi mfundo zazikuluzikuluzi ndizozama ndipo zimapereka chiyembekezo chopanda malire pamakampani amakono opanga makina.

Nthawi yotumiza: Nov-02-2022